Article: Streamline your supply chain with storage in Turkey

By Paula Pulsoni

The direct-to-site logistics model, although prevalent among sponsors in Turkey, can come with distribution challenges that are damaging for clinical trials by disrupting patient recruitment and treatment.

Clinical trial sponsors and pharmaceutical manufacturers are turning the country into a clinical research hub[1], due to its strategic location in the Eastern Europe, Middle East, North Africa triangle.

Given this unique location and ability to bridge the physical, cultural, and commercial gap between East and West, Turkey is quickly becoming an emerging market for clinical trial growth[2]. The Turkish pharmaceutical market is forecast to grow at a CAGR of 17.3% (±4.4) between 2018 and 2023, reaching TL78.1 billion by 2023[3].

So, there is a pressing need to develop solutions that mitigate the inherent risk within the direct-to-site model and drive resilience into the distribution chain.

A challenging supply chain

With the growth in Turkey comes inevitable challenges. As with many locations with a direct-to-site model in place, there are critical steps that need to be flawlessly executed for every shipment:

- Arrive in-country as scheduled, from a manufacturing site

- Customs need to be cleared within a specified timeframe

- The last mile covered through a domestic distributor

- Delivery made on time in full to the assigned responsible team to protect any blinding trial design

- Manage any temperature deviation to determine product availability in the shortest time possible

Variables, such as time to clear customs, can make it problematic to accurately determine a delivery window. In turn, this makes having the authorized consignee ready to receive the products at the clinical site incredibly challenging.

If there is an error at any of these five steps and the transit time is extended, temperature deviations may result in the clinical trial material needing to be quarantined. If the material cannot be released for use, the only solution left would be scheduling a new shipment from origin, resulting in potential treatment delay.

The great debate: in-country vs direct-to-site

Sponsors generally have two options to manage the logistics for their trials, both with associated challenges:

- Direct-to-site: an option of choice for countries close to a central storage location. However, the supply chain may gain in efficiency at the expense of effectiveness. This model has an increased risk due to complexity to achieve on-time deliveries, and coordinate staff to receive the shipments especially critical for blinded trials.

Furthermore, longer transits bring higher temperature deviation risks. In 2019, World Courier Turkey distributed 1672 clinical trial shipments; these were all direct-to-site[1]. Our proprietary data shows that the average time to clear an international clinical trial shipment through customs has been 93.3 hours. Given that it can take nearly four days just to exit the airport, plus the impact of transit times, the turnaround to reach a patient is lengthy and can be extended in the event of a temperature deviation.

- In-country depot storage: an option for countries with complex customs processes and/or located at a far distance from central storage facilities. The supply chain gains complexity as multiple logistics providers are engaged in the chain. While stock is closer to patients facilitating the last mile of the supply, inventory planning becomes more relevant to avoid waste of investigational materials.

Mitigating risks and driving clinical trial success

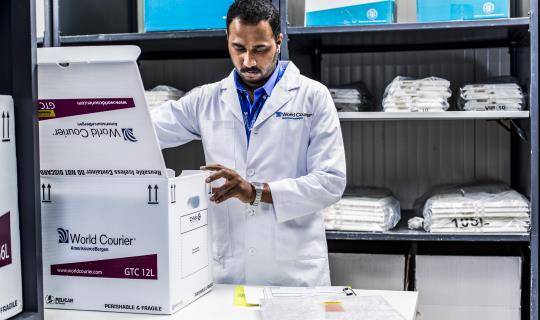

With the completion of a GMP-compliant depot in Istanbul in July 2020, World Courier can provide an alternative to the direct-to-site model. In-country distribution means more clinical trial products get to where they are needed, more rapidly.

By storing investigational drugs in the country, World Courier can save time, reach patients with a faster turnaround while ensuring flawless execution of the delivery process. The consequent mitigation of temperature deviation risks reduce costs to address unexpected contingencies

The benefits of this model are evident during COVID-19, where supply chains with in-country solutions have shown resilience through alternative last-mile distribution solutions, thanks to inventory proximity to patients.

Additionally, when the Turkey depot is used with other facilities in the World Courier network, there will be lower administrative costs for our clients due to single quality system, harmonized operations and centralized trial management.

World Courier’s one-stop solution model helps sponsors deal only with one provider for the entire process – facilitating simplicity in a complex supply chain.

How the in-country model works

For every clinical trial, our team of experts will create a specific set of instructions and training on our project-specific client requirements.

Material received in Turkey is inspected before release for dispatch on request. Strict temperature controls and fully redundant facilities are in place to prevent any material loss during storage.

When an order is received by the Turkey depot, it can be coordinated on the day with the authorized consignee able to select a specified delivery window. Our agility in action will allow investigators and site pharmacists to focus on their core responsibilities.

In the case of delays, we can quickly action contingency plans due to our domestic presence. Our depot can also provide storage for APIs, medical devices, advanced therapy medicinal products, cells or tissue samples, etc.

Our clients can access a real-time web-based platform to monitor inventory levels and distribution. Combined with existing transport capabilities, World Courier can offer more control, flexibility, and agility throughout the supply chain.

Summary

At World Courier, we work hard to be a trusted partner, delivering flawlessly executed logistics solutions across Turkey and beyond. Our in-country model increases predictable performance which ultimately reduces uncertainty and the associated costs of logistics failure.

[1] Clinical Trials in Turkey: https://www.ncbi.nlm.nih.gov/pmc/articles/PMC3878463/

[2] Turkey’s Pharmeceutical Vision 2023 Report: https://www.pwc.com.tr/en/publications/industrial/pharma/pdf/ilac-sektoru-vizyon-2023-raporu-eng.pdf

[3] IQVIA Market Prognosis 2019-2023 – Europe and Turkey

[4] WC Internal Data – Clinical Trial Shipments into Turkey CY2019